When you need to outsource production for your water-based dispersions and emulsions, our state-of-the-art facilities and 50 years of manufacturing expertise will provide the cost-effective solution you require.

Supported by our technical and manufacturing teams who have a wealth of experience, we can provide tolling services meeting your exact specifications, compliance and processing requirements for a wide range of market sector applications.

Why partner with us?

With over 50 years of experience in the production and development of aqueous dispersions and emulsions, we’re a trusted name with a global presence. Strategically positioned manufacturing sites in the UK, Malaysia and the USA, service local markets across Europe, Asia-Pacific and North America.

Our ISO 9001 and 14001 certified facilities deploy state of the art equipment and processes enabling us to produce to the highest quality and environmental standards.

With fast and efficient turnaround times, we have the flexibility to manufacture batch sizes from 250kg to 20,000kg.

Our core capabilities

We offer a flexible range of process technologies to meet an equally wide range of manufacturing requirements.

Emulsification: Ambient - 250kg to 20,000kg

Emulsification: Pressure - 400kg to 1000kg

Dispersion: Ambient - 250kg to 20,000kg

Blending and mixing: Liquid-liquid and solid-liquid

Milling and grinding: Custom particle size reduction

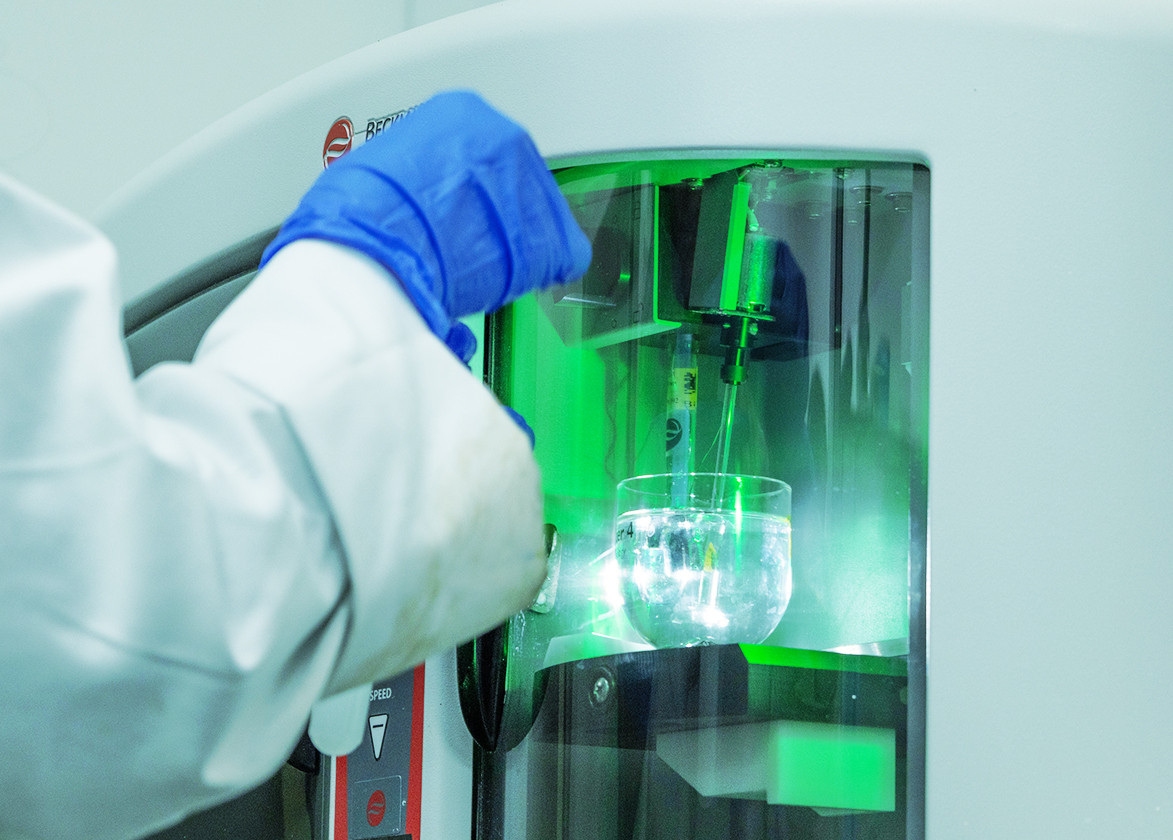

State of the art equipment

Consistency, quality and compliance are critical to every successful formulation. So, when you need to scale up without compromise, our advanced facilities enable you to achieve this. Each is equipped with the following:

316 stainless steel vessels (250kg–20,000kg)

Rotor stator high shear mixers

60 litre bead mills

Ambient emulsification

Pressure emulsification

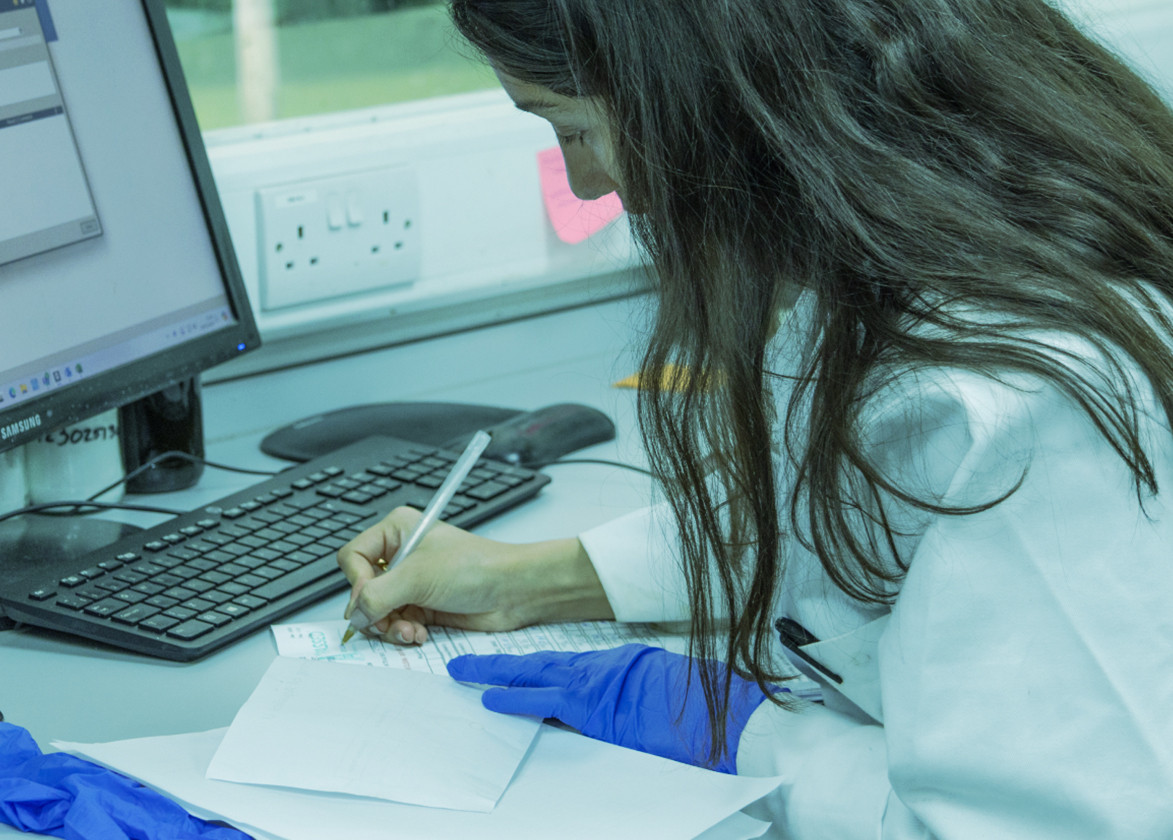

On-site QC laboratory for in-process and final analysis.

Value-added services

For every formulation, consistent manufacturing excellence is critical. So, in addition to our production facilities, our technical teams can enhance your manufacturing outcomes with a comprehensive range of support services.

Markets

Our manufacturing facilities support the following key market sectors.

Innovation

Discover More

Regulatory

Discover More

Sustainability

Discover More